Connecting a VNA without a Torque wrench…?

Lately I posted an article about specs of different types of cables on Linked-In. I’ve kept on wondering….I see so often people connecting cables to their equipment without using a Torque wrench.

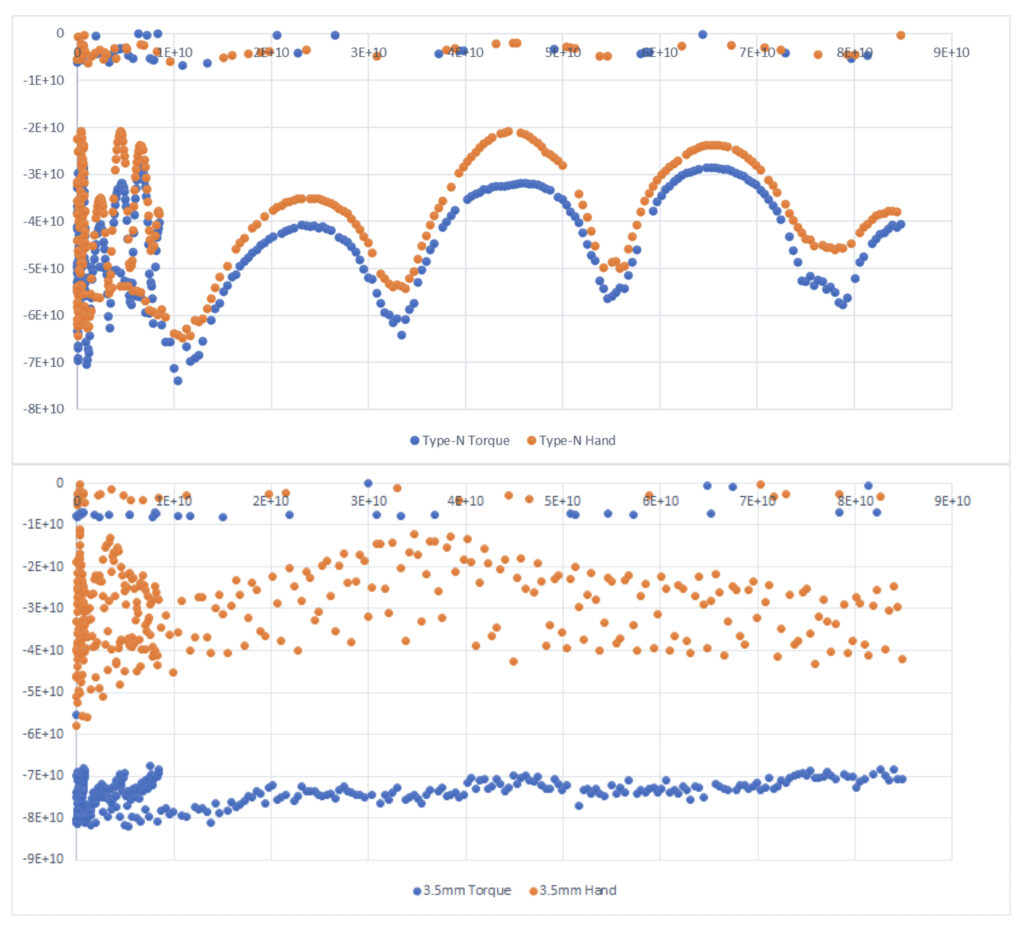

With Maury’s “Insight S-parameter calibration and measurement software” I’ve made some measurements on a type-N- and a 3.5mm connector. Both were characterized with and without a Torque wrench. The procedure within the software is simple. Just tighten and un-tighten the connector a number of times.

Looking at result of this connector repeatability characterization already significant differences are visible. There seems to be more consistency between the use with- or without a Torque wrench on the Type-N connector compared with the 3.5mm connector.

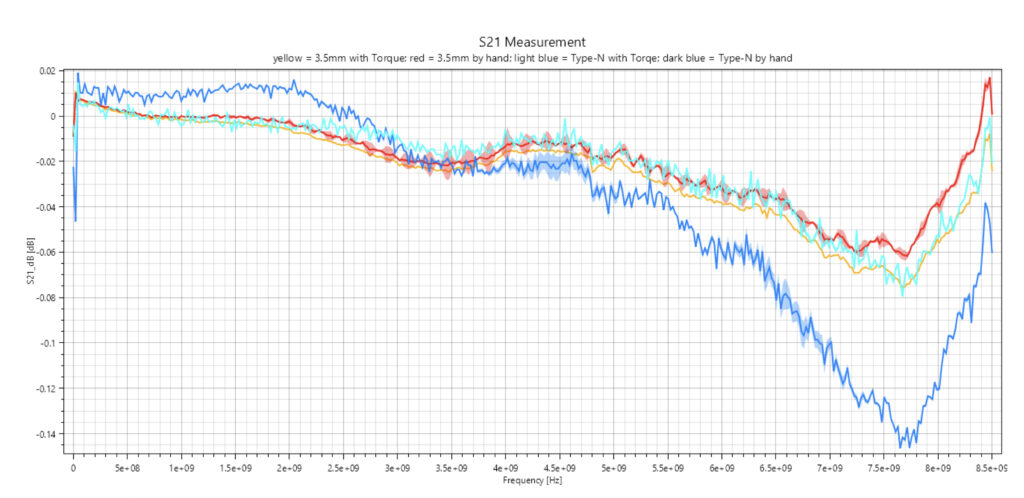

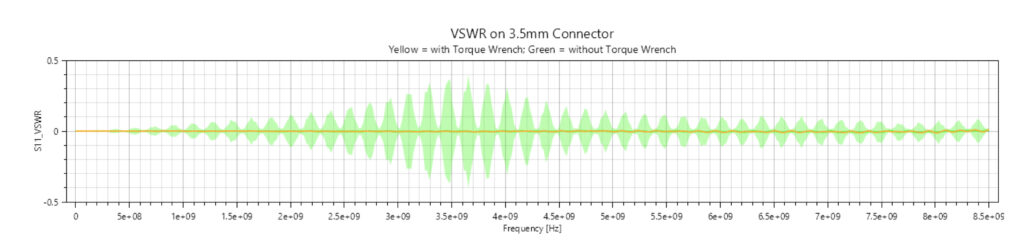

To determine the influence real measurements two measurements were made. a s11-VSWR and s21-measurement from 9KHz to 8.5GHz. There surprisingly not much difference between results of the four different situations for the s21-Measuremnt. “Insight software” didn’t show much deviation between the four measurements and also there is not much contribution on error. Keep in mind, this is only added error of the connector, not the total VNA Setup.

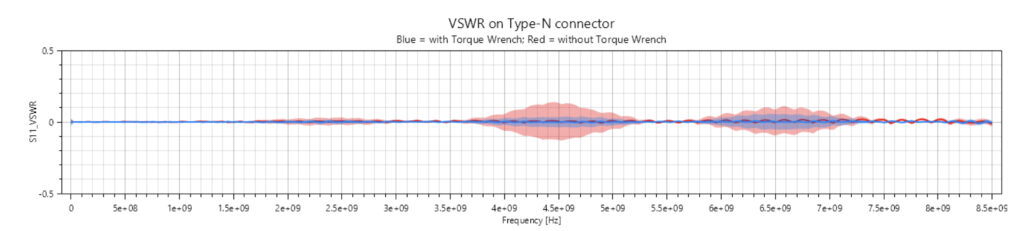

In terms of reflection “Insight” shows a different picture. As showed in previous graphs, Characterization on Type-N was pretty consistent. This is also being shown within the results of a VSWR Measurement. To compare results Y fixed the scale on +/- 0.5dB. Furthermore the measurement is normalized on the situation where connectors were tightened with a wrench. The max error in case connectors are tightened by hand is 0.25dB. With Torque wrench the max error is slightly more than 0.1dB

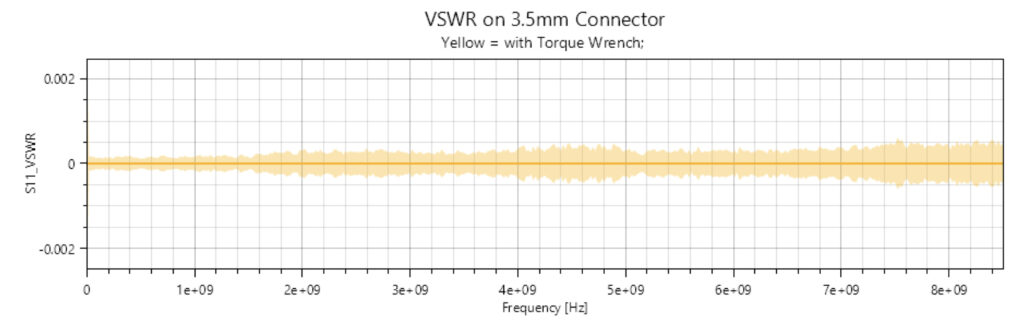

In case of the 3.5mm connector there is much more difference. Using a Torque wrench resulted in a repeatability of 0.001dB. This is the connector you find on Maury’s “StabilityPlus cables.

Skipping the Torque Wrench showes worse results compared with results of the type-N connector, 0.8dB.

To conclude, it’s always better to use a Torque wrench but is less critical with type-N connectors. However, repeatability and accuracy is critical in most of the situations. Why else is spend lots of money on VNA’s and all components within the measurement setup. A little Torque wrench is your best friend as it truly makes the difference.

Check-out the website of Maury Microwave for more information by following the links:

https://www.maurymw.com/Interconnect_Solutions/TW_Wrenches.php

https://www.maurymw.com/Interconnect_Solutions/Stability_Plus.php

https://www.maurymw.com/Precision/Insight_Software.php

For more information, please don’t hesitate to contact me. I’m open for suggestions and comments so please share these as well.

Best regards,

Dirk Faber, Hitech BV

HITECH

HITECH